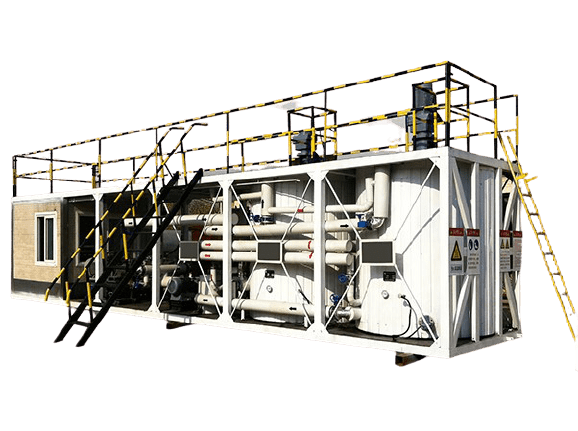

Polymer Modified Bitumen Plant

Polymer Modified Bitumen emulsions are a special class of bituminous emulsions. Polymer modified bitumens are among the most advanced bitumens used for micro surface coatings. Production and usage conditions are in European Standards.

Special bitumen is required for intense traffic roads and regions with high level day and night temperature differences. These special bitumens can be prepared in ATS Polymer Modified Bitumen Plants in accordance with European Standards.

On coating surfaces thanks to Modified Bitumen;

More water resistant floor,

Higher resistance to crack formation and spreading,

In road pavements, a binder that is more resistant to fatigue and permanent deformation is obtained.

Two types of Polymer Modified Bitumen Plants are produced as Single-cycle and Multi-cycle.

In a single cycle system, 4-25 t / h capacity,

Modified Bitumen can be produced in a multi-cycle system with a capacity of 1-9 t / h.

In the Polymer Modified Bitumen Plant;

- The bitumen pipeline is fully insulated and heated using transfer oil with a precise temperature control system.

- Bitumen equipment, tanks and pipelines are isolated to protect the system from corrosion, ensuring a longer-lasting facility use.

- The materials between the chambers are prepared in accordance with their recipes with precise measurements such as load cell and flow meter.

- System monitoring and increasing system efficiency with PLC control,